When it comes to the intricate world of braided mesh tube-films, understanding their crystal structure becomes crucial. These films often feature crystallites with distinct forms, ranging from well-defined crystals to amorphous structures. The amorphous structure, for instance, lacks long-range order and typically consists of extremely small grains—less than 2 nanometers—and these grains are randomly arranged. This type of structure is commonly found in high melting point metal films, high melting point non-metallic compound films, certain carbon-silicon-germanium compound films, and co-precipitation films made from two incompatible materials.

Polycrystalline structures, on the other hand, consist of crystallites that are randomly oriented, with grain sizes ranging between 10 to 100 nanometers. These are typically seen in low melting point metal films. Another fascinating structure is the fiber structure, where the grains within the film exhibit a preferred orientation. A single fiber structure involves crystallites that are preferentially oriented in just one direction, while a double fiber structure allows for orientation in two directions. Various piezoelectric microcrystalline films also fall under this category.

Weaving the network tube is a complex process, and the appearance of the fiber structure can emerge during different stages—nucleation, growth, or even during the annealing process. Single crystal structures, which are predominantly formed through epitaxy, play a significant role here. Semiconductor epitaxial films are another key example. Under specific conditions, the microstructure of the film might transform, such as transitioning from an amorphous state to a more ordered polymorphic form. These changes significantly impact the properties of the film.

In most cases, the crystal structure of the crystallites in the film mirrors that of the bulk material, though differences in grain orientation and size may exist. One critical factor to consider is lattice mismatch. When the lattice constant of the film material doesn't align with that of the substrate, substantial internal stress and surface tension arise in the braided web film. At the interface, the crystal lattice undergoes distortion to better fit with the substrate.

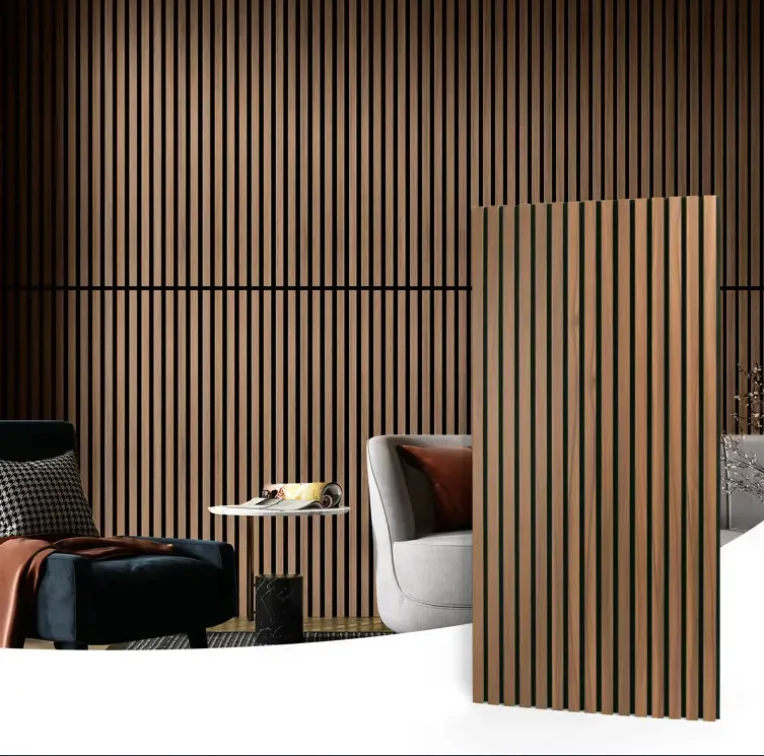

For those interested in learning more about our advanced materials and technologies, please visit our company’s official website at http://. We are committed to delivering cutting-edge solutions tailored to meet your needs. Interior Aku panel Wooden Slat Acoustic Panels Sound Proof Slated Wood for Hotel Application Wall Decoration Shandong Zeen Decoration Material Co., Ltd. , https://www.zeendecor.com

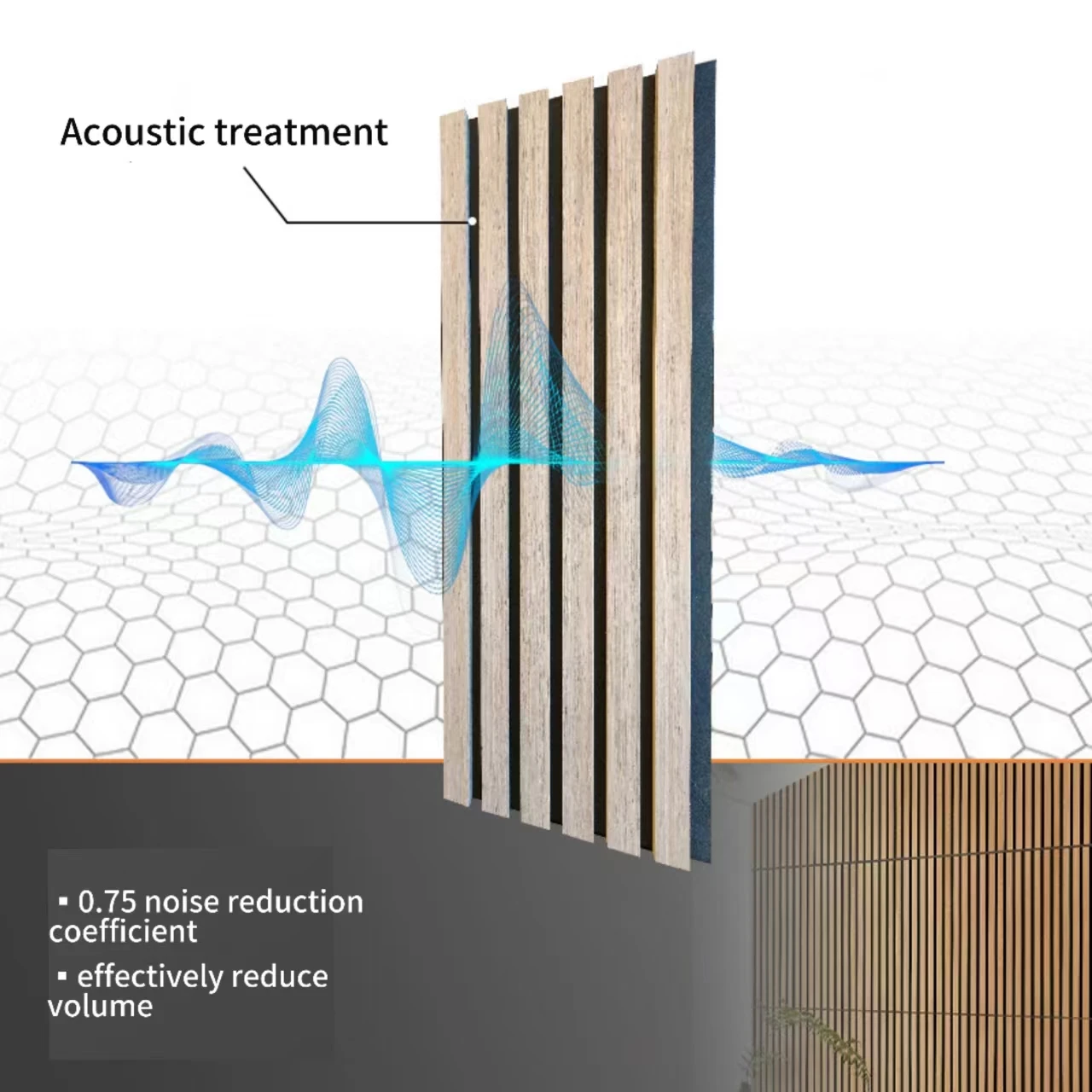

Our sound-absorbing panel factory is a leading producer of high-quality sound control products. Our panels are designed to reduce sound transmission and reflection within commercial, industrial and residential environments. With a focus on innovation and technology, our factory employs state-of-the-art production techniques to manufacture sound-absorbing panels that meet the highest standards of acoustical performance.

Weaving mesh tube - film related knowledge

The Polyester Fiber Wooden Grille Acoustic Panel is a highly effective sound absorption product that offers an aesthetically pleasing solution to control noise levels in various applications.